Ground and Air Source Heat pumps have been tagged as the heating systems of the future due to the numerous benefits they possess, unlike their conventional counterparts. But how long do these heat pumps last and continue to offer these benefits?

Air source heat pumps usually last for around 10-15 years, whereas ground source heat pumps should work reliably for 20 years or more. The lifespan of your heat pump is dependant on regular maintenance and a service plan is essential.

Other factors that influence heat pump lifespan include the climate, location, power demand on the system, the amount of use, and the installer’s expertise.

The rest of this article will go into detail on the factors that influence the lifespan of heat pumps. This would also contain the best type of heat pumps to purchase when buying one.

The lifespan of Ground Source Heat Pumps

Ground source heat pumps on average last for more than 20 years. The most expensive and difficult to install part is ground loops which if properly installed can last more than 50 years. This should always be done by a professional installer.

The lifespan of the pump

The life expectancy of a heat pump is determined by several factors, including the type of heat pump, your location, and how well the heat pump is maintained. The weather in your location, for example, has a significant impact on the heat pump’s lifetime. When the area endures longer and colder winters, a heat pump’s lifespan might be shortened.

The life span of the heat pump also depends on the manufacturer of the pump. Different manufacturers offer different warranties and life span guarantees. Heat pumps from Daikin and Mitsubishi are the most resilient of the bunch, having a reported service life of over 25 years if managed properly.

The lifespan of the heat exchanger

The lifespan of the heat exchanger part of the system (looped pipes) is usually very long and good installation can further increase it. Professionals who have ideally received training from manufacturers or other recognized authorities should install the ground heat exchanger. It is critical that there are no subsurface mechanical connections that cannot be mapped and accessibility gained if necessary. The best approach would be to keep the number of joints in the system as low as feasible.

Service life, maintenance expenses, pumping energy, capital cost, and heat pump performance are all affected by the pipe material utilized. For buried ground collectors, it is critical to utilize high-quality materials.

The lifespan of horizontal collectors vs. vertical boreholes for geothermal heat pumps

In terms of the physical installation, i.e. pipework, both ground loop and borehole systems should have a comparable predicted lifespan assuming the proper materials are utilized appropriately fusion welded. Both systems are expected to last more than 50 years, possibly longer because the polymers used should have less deterioration because they are not exposed to sunlight. Both systems would necessitate changing the glycol (heat transfer fluid) regularly.

Vertical borehole heat pumps may be more difficult to fix because the system is harder to access given the depth of the pipes.

Should you replace the whole system when the pump reaches the end of its life span?

The ground source heat pump system has three main components: heat exchanger, heat pump, and heat distribution system. Usually, the heat pump is the first component that reaches its end of life span. It can be replaced without replacing the other components. The only thing to be kept in mind while replacing is compatibility with the existing heat exchanger system and heat distribution system.

Which components expire first, and why?

The heat pump is the component that expires first and it all comes down to its compressor. The compressor, which is the portion of the system that raises the temperature of the heat-absorbing liquid, is usually the first part of a heat pump to fail. This component is continually moving, making it prone to burning out and making it inevitable that it will break down at some point.

You’ll have to decide whether to replace the entire heat pump or just the compressor if this happens. It may be more cost-effective to replace the entire pump if the heat pump is close to or over 20 years old. Plus, after two decades, heat pumps are expected to have improved considerably, implying that a new system will pay for itself even faster.

The other components like heat exchangers and heat distribution systems have fewer mechanical components, which makes their life longer.

Factors that reduce the lifespan and how you can increase the life span

A heat pump’s lifespan is determined by a number of factors, including the type of heat pump, your location, and how well the heat pump is maintained. Maintenance is the most critical aspect in deciding the longevity of your heat pump. Your heat pump should be checked every three years by a professional heat pump installer, but the great bulk of maintenance may be done by you. The following are some of the steps to take:

- Keep any outside components or coils clean. They may become dirty with usage, so clean them with a heavy-duty degreaser and then wash them down. Make sure the device is turned off first.

- Check the pressure and refrigerant levels. The refrigerant is essential to the effective operation of your heat pump and should be checked on a regular basis, just like the oil in your automobile. If the level is correct, you’ll be able to see if there’s a leak or another issue with the system. You should have an active service plan, so that the system is regularly maintained by a professional who can quickly and competently test the necessary levels.

How do you know if the GSHP needs replacing?

Following are some signs, which indicate a possible replacement

- Increasing energy costs. Geothermal HVAC systems are designed to be energy efficient. If they begin to exhibit symptoms of inefficiency, there’s a strong probability you’re dealing with a problem.

- Airflow has been reduced. A blocked filter or a failed fan or motor are the most common causes.

- The heating is uneven. It’s possible that the heat pump or ducting is malfunctioning.

- Reduced temperature. Leaking loops, heat pump failure, blocked ducts, clogged filters, and other factors can all contribute to this.

- Loud or rattling noises This is usually a mechanical problem that should be addressed right away to avoid further costly repairs.

- Burning or chemical odors This might indicate a potentially perilous situation. Contact a professional as soon as possible.

How long do pool heat pumps last?

A pool heat pump may survive for 10 years or more with correct installation and maintenance. The demands on a pool heat pump, mainly due to the volume of water that needs to be heated, are greater, leading to a lower expected system life.

Does any particular type of GSHP last much longer?

No there is not. The typical heat pump lifespan is 15 years for most manufacturers, with some lower-end systems barely making it through 10 years. Some of the better and more dependable models can last up to 20 or even 25 years if serviced regularly and the installation is properly maintained. This is empirical data since more exact, trustworthy data is difficult to get from outside of trade professionals’ expertise.

Cost of repair and replacement

The following repair and replacement expenditures may be incurred based on data by the home advisor.

- Heat Pump Issues can cost you around. $50 to $1700. Parts wear out and need to be replaced.

- $75-$200 for loop leaks. A licensed specialist can swiftly diagnose and remedy the problem if an unusual leak happens.

- $150-$200 for hard water maintenance If not properly maintained, hard water accumulation can be a problem. To descale the pipes and enhance efficiency, a professional might run an acid wash through the system.

- Cleaning ductwork costs $250-$500. The cost of duct cleaning is definitely worth it to help extend the life of your filters and boost blower effectiveness.

- Repairing ductwork costs $30-$50 for each linear foot. The cost of ductwork repair is justified by the energy savings they may give. If you detect an increase in heat pump consumption without any other factors.

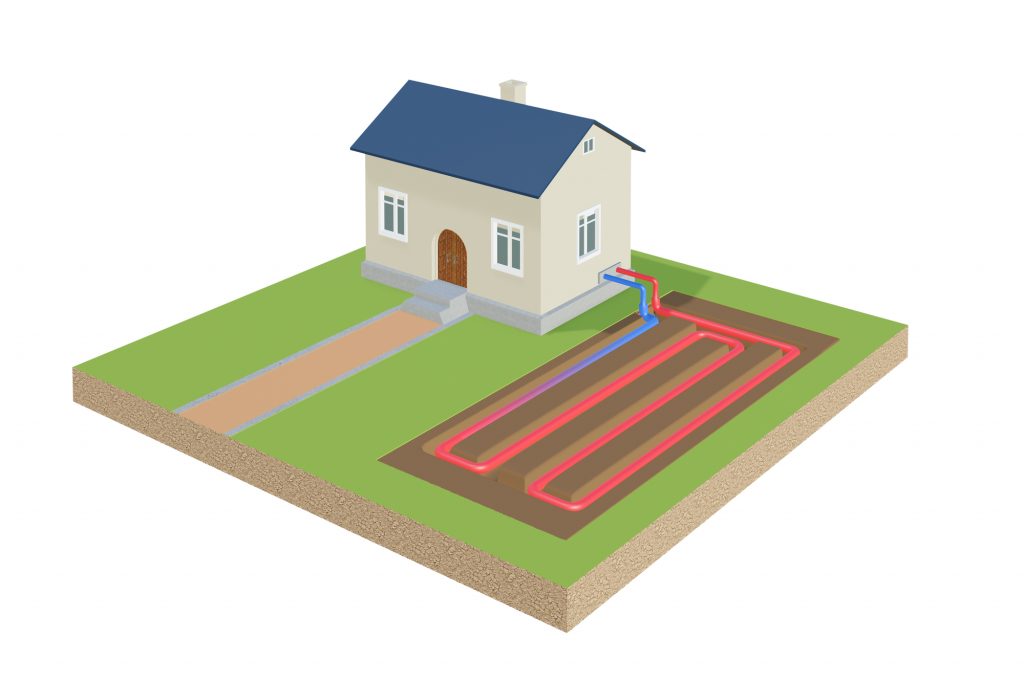

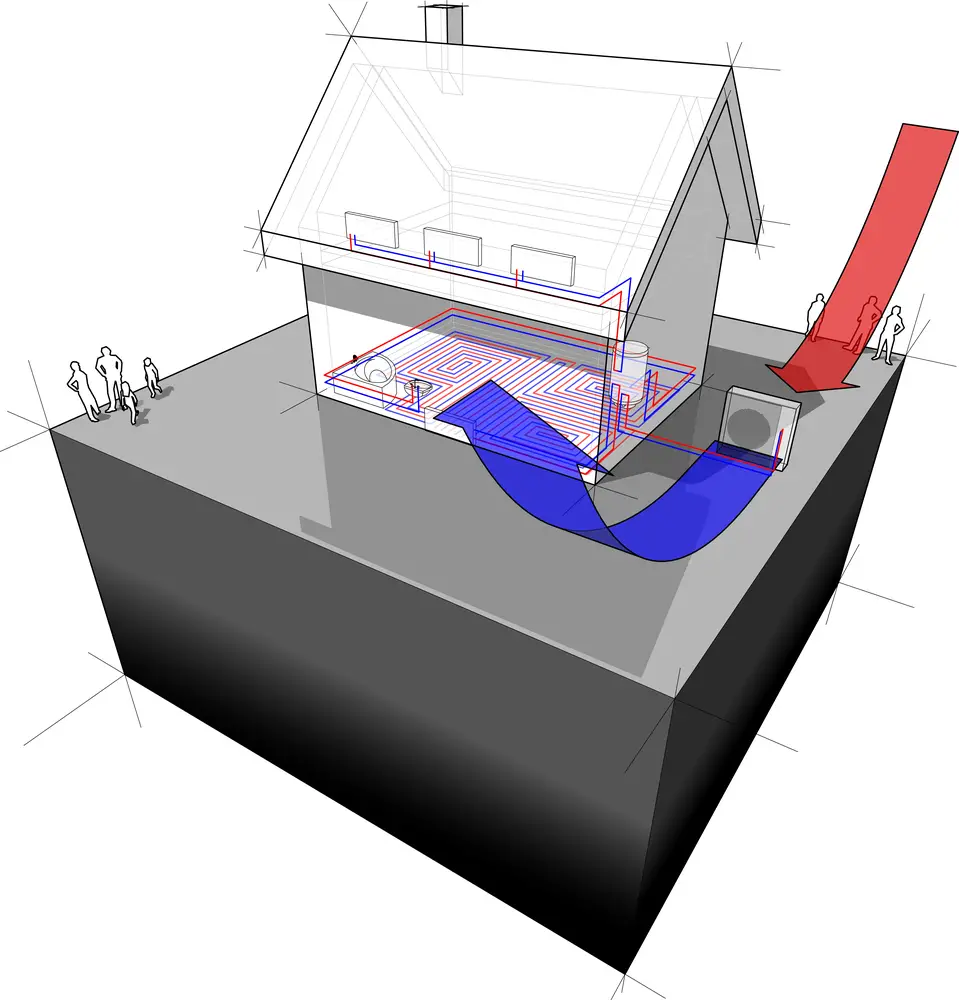

Reminder of How Ground Source Heat Pumps Work

About 10 feet below the surface, the ground has a constant temperature of 10-12°C year-round, regardless of weather conditions. That’s because the ground soaks up the sun’s rays and stores the heat. Geothermal heating and cooling systems work by tapping into this energy.

An underground pipe system filled with a refrigerant fluid is installed to access the ground’s constant temperatures. In summer, when the earth is cooler than your home, the refrigerant transfers heat from your home to the ground. The warmer fluid naturally cools off as it comes into contact with the ground. The fluid then returns to your home and extracts more heat.

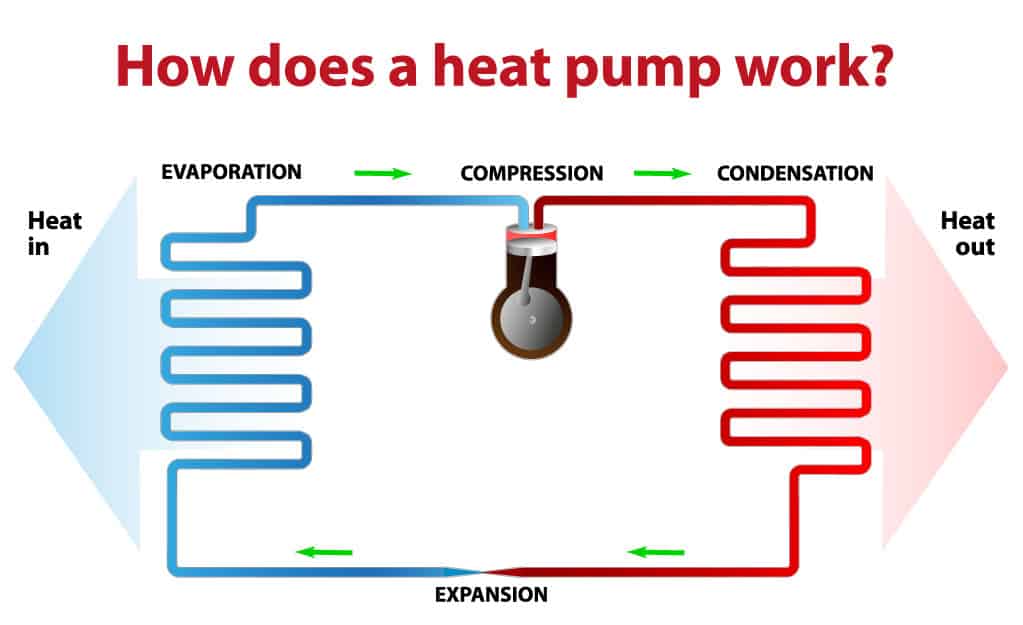

First, let’s see how a ground source heat pump works in more detail. How does the heat transfer from the ground to a radiator in the first place?

- A ground source heat pump takes advantage of the sun’s energy stored underground. Underground pipes, designed to allow heat transfer through their walls, are installed to access the ground’s constant temperature.

- The fluid running through the array of ground pipes is a mixture of water and antifreeze. This mixture absorbs the low-grade heat from the ground array as it circulates. Lots of heat energy can be absorbed this way due to the length and surface area of the pipes.

- On its return to the control hub, the water-antifreeze mixture enters a heat exchanger, also known as an evaporator. The heat exchanger has two sealed-off compartments, one housing the flowing water-antifreeze mixture, and another holding a volume of refrigerant. The two liquids never mix together.

- The heat energy in the water-antifreeze mixture, which has been absorbed from the ground, then diffuses through the pipes in the heat exchanger and into the refrigerant liquid, which then boils into a gas due to its very low boiling point. The water-antifreeze mixture continues to circulate back into the ground loops for another cycle.

- The gas is then fed into a compressor, which increases the pressure of the gas and hence its temperature. This hot gas then flows into a second heat exchanger, known as the condenser. This component is very similar to the evaporator heat exchanger which transferred the heat from the water-antifreeze mixture. However, this time it transfers heat from the refrigerant gas and into a flowing water circuit which can then go off to heat the home via radiators or underfloor heating, or perhaps heat the water supply to the taps.

- The refrigerant gas that has lost its heat then condenses back to a liquid as it cools beneath its boiling point. It then passes through an expansion valve, reducing the temperature and pressure and circulating back to the evaporator heat exchanger ready to meet more warmed water-antifreeze mix and to repeat the cycle.

You can learn more about how radiators combine with ground source heat pumps by watching this video from Kensa Heat Pumps on Youtube.

In the wintertime, the underground temperature is higher than the temperature inside your home. Therefore, the refrigerant inside the pipes transfers heat from the ground to your home. The fluid travels via a compressor, which raises its temperature. An underfloor heating system is used to distribute the heat inside your home. The temperature inside your home remains comfortably warm.

The lifespan of Air Source Heat Pumps

Air source heat pumps last for shorter times than ground source heat pumps. The average life span of an air source heat pump is between 10-15 years. If it is exposed to more corrosive environments like marine environments, the average life span may drop even further.

Good installation, usage, and maintenance can further increase the lifespan of the air source heat pump to 20 years. Heat pump installation should be undertaken with extreme attention and by specialists who will guarantee that the necessary processes are followed. Before installation, proper capacity planning, mode of usage, and chemicals utilized must be performed.

When the heat pump reaches the end of its lifespan, does the whole system need to be replaced, or just the pump unit

An air-source heat pump has three main components. An outdoor heat exchanger unit, heat pump, and a heat distribution system. The outdoor heat exchanger might need to be replaced first if it is located in harsh outdoor environments. Otherwise, it is always the heat pump due to its compressor unit being the most vulnerable part.

Factors that reduce the lifespan of air source heat pumps

Maintenance Level

Increase the longevity of your heat pump by performing routine service maintenance. This involves cleaning the devices regularly, changing the air filters on a regular basis, and ensuring the defrost mechanism works properly.

Once again, a regular service by a professional will help to increase the lifespan of your air source heat pump.

Climate

If you have longer and colder winters, your heat pump will have to work harder and longer than normal. Therefore you can expect a shorter lifespan from a heat pump that has more demands placed upon it.

Location

Heat pumps have a lower lifetime in coastal areas. This is due to the saline environment, which causes corrosion and gradually destroys your equipment over time. Heat pumps positioned in coastal locations are more prone to corrosion than heat pumps located within.

Installation

Heat pump installation should be conducted with extreme attention and by specialists such as aspiration energy who will guarantee that all processes are followed correctly. Before installation, proper capacity planning, mode of usage, and chemicals utilized must be performed.

Usage

Overuse or inappropriate use also shortens the life of your heat pumps. Running the system with the doors and windows open shortens the life of your heat pump.

How do you know if the ASHP needs replacing?

- Heat pumps are claimed to be cost-effective. However, even the most efficient of them lose efficiency after a few years. The performance and efficiency of a heat pump will degrade over time if it has been used practically continuously. As a consequence, your energy cost will begin to rise until it is significantly greater than it is now.

- It is now common for your heat pump to require maintenance from time to time. However, if you find yourself calling in the technician more frequently than normal, take heed.

- If you discover that the heat pump is producing chilly air despite being set to a high temperature, or warm air despite being set to a lower temperature, you should investigate more.

- Heat pumps are not meant to leak or let out moisture within the house. If you see this, it suggests the condenser is malfunctioning.

- The heat pump is almost ten years old – consider planning a replacement, taking into account current performance.

Does any particular type of ASHP last much longer?

You should look into the following factor if you looking for ASHP’s types that last longer.

- The heat pump’s construction quality.

- The heat pump’s efficiency rating.

- The era and technology of the heat pump.

- Maintenance services offered

What can you do to lengthen the lifespan?

- Regularly inspect air filters. Check your air filters regularly if your heat pump system has them. If they become obstructed, the system’s efficiency suffers. Filters should be cleaned or replaced as needed.

- Examine the outside unit. Check for snow, ice, leaves, dirt, and other material around the outside unit. This applies to the heat pump’s top, sides, and bottom.

- Prune the bushes and plants surrounding the apartment. To allow for appropriate ventilation and service, vegetation should be moved back at least 18 inches on all sides.

- Examine the fan blades. Check the fan blades for dirt and debris after turning the device off. If required, clean.

Verdict and Conclusion

The Lifespan of a ground source heat pump is certainly more than the air source heat pump if proper and careful installation is followed. The following table compares life spans and replacement components of both heating systems considering the proper installation and suitable environments.

| Ground Source Heat Pumps | Air Source Heat Pump | |

| When you would need the first replacement | 20 years or more | 10 years |

| Which component needs to be replaced first | Heat pump | Outdoor heat exchanger |

| Replacing the complete system with a new one | More expensive | Less expensive |

| When you need the complete system replacement | At least after 50 years | Variable, aim for 15-25 years |

| Which one has easy complete system replacement | Difficult as underground pipe loops are difficult to reinstall | Not very difficult |

| The lifespan of pool heat pumps | 10 years | 10 years |

The factors that affect the life span of air source heat pumps are similar to that of geothermal heat pumps. For this reason, a similar course of action should be taken to get the best out of them.

Check out all our other information on air source heat pumps here:

- What temperatures do air source heat pumps produce?

- Will air source heat pumps work in an old house?

- Air Source Heat Pump Pros and Cons

- Should air source heat pumps ever be turned off?

- Can air source heat pumps be combined with radiators?

- How efficient are air source heat pumps? Costs and Efficiency explained

- Can you combine air source heat pumps with underfloor heating?

- How long do heat pumps last? Air Source Heat Pump Lifespans

- Are air source heat pumps safe?

- Are air source heat pumps environmentally friendly?

Check out all our other information on ground source heat pumps here:

- What Temperature do Ground Source Heat Pumps Produce?

- Do Ground Source Heat Pumps work in Winter?

- Are Ground Source Heat Pumps good for the environment?

- Can Ground Source Heat Pumps work with Radiators?

- Can you combine Ground Source Heat Pumps with Underfloor Heating?

- How much land do you need for a Ground Source Heat Pump?

- Can Heat Pumps Cool?

- How long do heat pumps last? Ground Source Heat Pump Lifespans

- Are ground source heat pumps safe?